TROCA DE PARAFUSOS DO CABEÇOTE

Dicas Técnicas

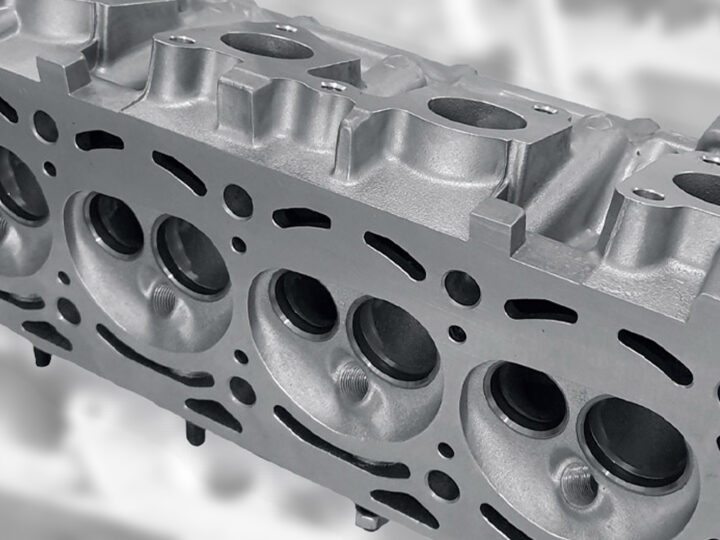

Os parafusos são os componentes que garantem a união perfeita entre o cabeçote, a junta e o bloco do motor, graças à pressão superficial que eles geram nas peças ao serem fixados.

Em motores mais antigos, sua utilização se dava apenas com a aplicação de torque. Devido a perdas por atrito, este método não gera uma tensão uniforme em todos os parafusos do cabeçote e exige que sejam retorqueados após certo tempo de uso do motor.

Acompanhando a evolução das novas gerações de motores, passou-se a empregar o método de aplicação de torque seguido de ângulo de aperto. Este método, previsto na norma/roteiro VDI 2230, é mais preciso no controle da força aplicada no cabeçote, gerando uma tensão mais uniforme e não necessitando que os parafusos sejam retorqueados.

Kit de Parafuso para Mercedes Benz

Por que trocar os parafusos?

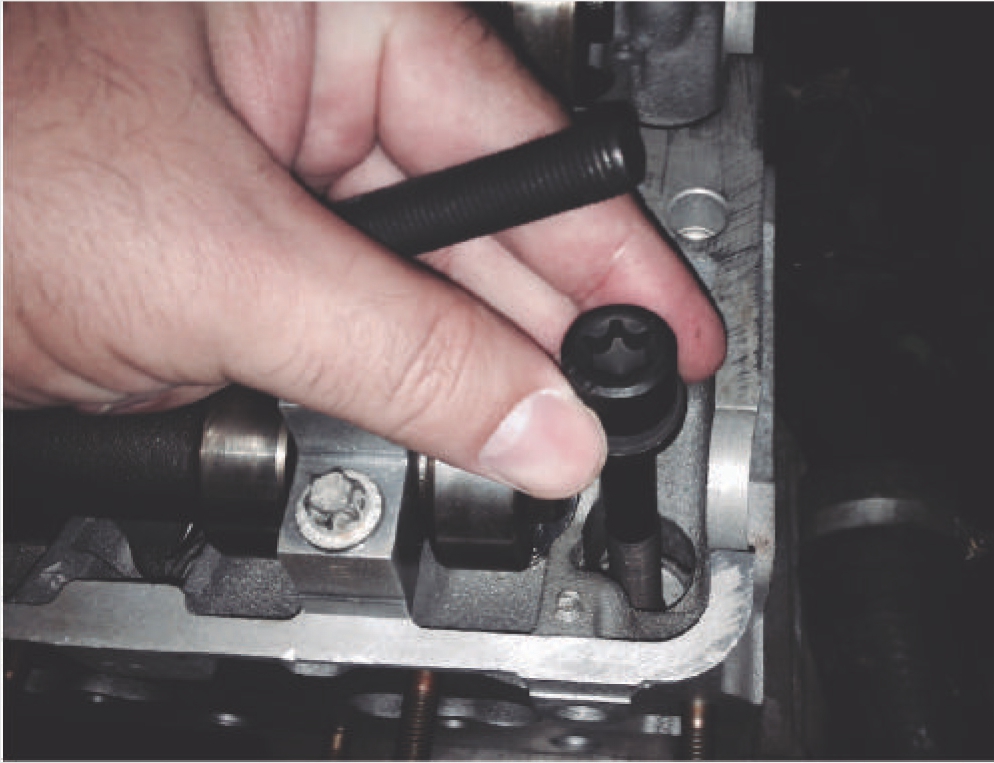

Com o emprego do método torque-ângulo, os parafusos são deformados plasticamente, ou seja, são alongados de forma que seu comprimento não retorna mais à dimensão original depois de desmontados. Juntamente com este alongamento, ocorre uma redução no seu diâmetro. Esta redução faz com que a resistência do parafuso diminua e coloque em risco a confiabilidade da união e da vedação do conjunto, caso ele seja reaplicado.

Portanto, uma boa fixação e vedação adequada somente serão possíveis se as recomendações de montagem forem seguidas conforme o especificado. Os parafusos que já foram submetidos à deformação plástica não devem ser reaplicados. Somente desta forma os indesejados vazamentos e queima da junta, custos de reparação que poderão ser completamente evitados.